With the development of industry, small pellet mill is very popular with customers. As a pellet mill manufacturer, GEMCO's technology research and development should keep pace with the times. High efficiency, high yield, energy saving and consumption reduction become the essential characteristics of energy machinery. Then how can we make the small pellet mill efficiently produce?

The operation of small pellet mill is relatively simple, but it should be properly operated and maintained in the process of use, which directly determines the service life and efficiency of the small pellet mill. This statement is verified by a professional tester of our company. Under his careful maintenance, the output of a very ordinary small pellet mill is far beyond the expected output, and the mechanical parts rarely fail. An example is the best persuasive force.

Finally, the selection of raw materials is consistent with the small pellet mill. It is best to configure a single model or production line equipment under the manufacturer's recommendation to ensure maximum utilization of fund. After finding the right models, some small skills and experience in the production process can ensure the maximum interests of the customers. Contact us now!

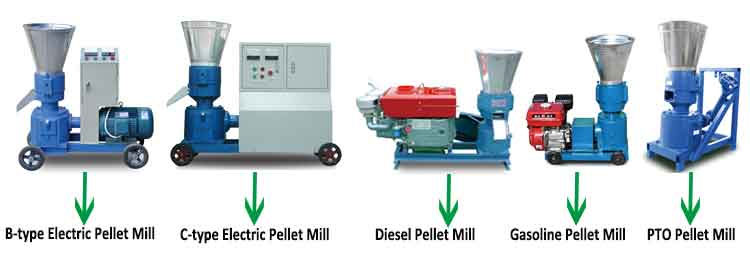

Our small pellet mill is a new type wood pellet processing equipment, which is also called flat die pellet machine, small wood pellet mill or small pelletizing machine. With the development of industry, customers are becoming more and more interested in small pellet mill. However, many customers do not know where to buy a small pellet mill with high quality and good price? Our company (GEMCO) specializes in the production of pellet mill. Reasonable design, compact structure, safe and durable. After being popularized, the effect is good. The small pellet mill can process sawdust and other raw materials into wood pellets. It has the advantages of less investment, high efficiency, energy saving, good economic efficiency, simple operation, convenient operation and maintenance. The screen can be replaced in the small pellet machine, so it is well received by our customers.

If you want to buy a small pellet mill, you can contact us. Our small pellet mill can be used in processing straw, sawdust, grass powder, etc. We can also customize the pellet machines according to the customers' raw materials and needs.

Diesel pellet machine and screw conveyor are specially designed for our customer. The trial run is successful. Welcome to consult and order....

Diesel pellet machine and screw conveyor are specially designed for our customer. The trial run is successful. Welcome to consult and order....