Pellet mill spare parts

Importance of pellet mill spare parts

As we all know, there are many different manufacturers of

pellet mills, so as to the pellet mill spare parts. Thus, the quality of pellet mill which is assembled by different kinds of spare parts is different. So if you have pellet mills, the most important thing you should consider is the quality of pellet mill spare parts, which can improve the production capacity and lower the cost of economy, more important, you can extend the lifespan of the machine.

Different pellet mill spare parts

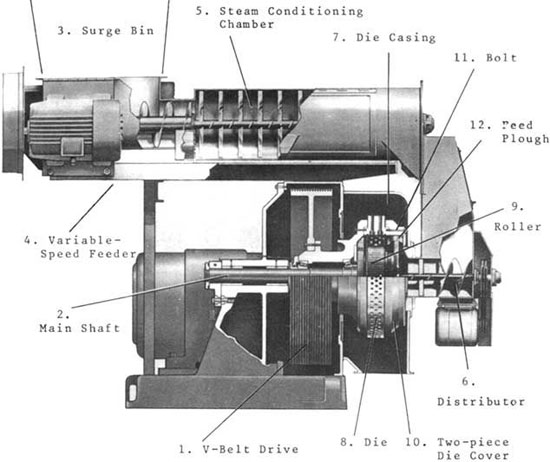

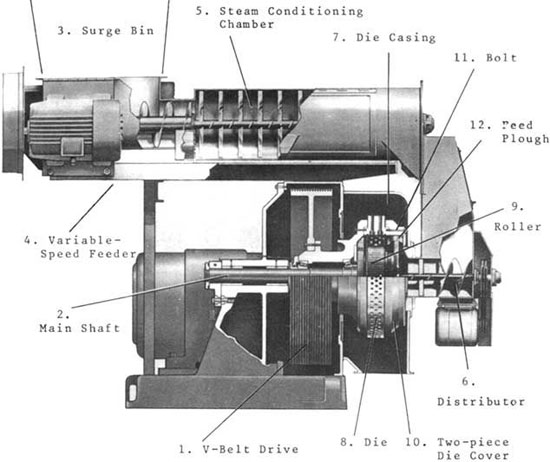

Nowadays, the most commonly used pellet mills are flat die pellet mill and ring die pellet mill. Just like a man, each parts of the body work well, the man can be healthy, the same to the pellet mills. Generally, the pellet mill spare parts contains pellet mill dies and rollers, eccentric shaft, main shaft, press cover, shearing pin, shearing pin cover and screws, etc. among these spare parts, dies and rollers are the most important parts.

Ring die of pellet mill for large scale pellets production

Ring die is very important to the ring die pellet mill which is usually used for large scale production, just as the heart to a man, choosing a reliable ring die plays an important role in producing high quality pellets, and can ensure higher output per hour and decrease power consumption. According to the feedback of our GEMCO customers, choosing the highest quality pellet mill ring die can guarantee the continuous production, and if you need to change ring die too frequently, it must spent much time and money which is harmful to the pellet production. So here are some tips for you to consider choosing preferable pellet mill dies because GEMCO is a professional manufacturer of pellet mill and pellet mill spare parts.

-

First, you should consider the material of the pellet mill dies, mostly, the raw material of making pellet mill dies are carbon structural steel, alloy structural steel, stainless steel, etc,. GEMCO generally adopts high quality alloy steel or stainless steel which makes sure the quality of pellet mill.

-

Second, the compression rate which means the rate of hole length and the hole diameter is a significant essential for consideration. Different raw materials need different compression rate.

-

Third, the smooth of the ring die surface, this directly affects the pelletizing, if the ring die surface is rugged, raw material jam may happen and you can’t making pellets continuously. What’s more, the diameter of each hole must the same which can ensure the pellets even and smooth.

Flat die of pellet mill for small scale pellets production

Compared with ring dies of pellet mills, flat dies are the ideal pellet mill parts, and flat dies are also crucial for pellet mills, it is the main parts during the process of making pellets, the difference between ring dies and flat dies lies that ring die is vertical while flat die is horizontal. GEMCO supplies different kinds of flat dies with different diameters from 2mm to 12mm for your different requirements. What’s more, flat dies are available in two different designs, one is the fixed die which is equipped with a rotating roller, and the other one is a fixed roller with a rotating die. Things need to be aware of choosing proper flat dies are the same to choose ring dies just can refer tips above.

Pellet mill rollers

Apart from pellet mill dies, the other very leading spare part of flat die pellet mill is pellet mill rollers. When pellet mill works, the pellet mill roller and dies extruding each other to make high quality of pellets. Generally, the pellet mill roller material must be anti-bearable and the roller shells are made of alloy steel. Pellet mill rollers usually have two types in structure: rotating die press roller and rotating roller due to the two designs of flat die pellet mills.

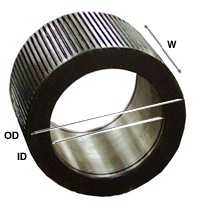

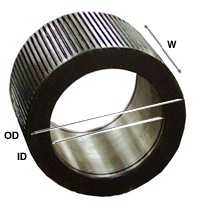

Roller shell

It is the surface of roller assembly, when raw materials are pressed against the die, they must go through the roller shell. The lifespan of roller shell is very important for the producing performance of pellet mill dies because of the close relation between roller shells and dies. A good roller shell is usually made of alloy or stain.

Specifications of Roller Shell

I.D. means inner diameter of roller shell: inside diameter is the most common identified dimension of a pellet roller shell and is always specified during the die selection.

O.D. refers to overall diameter of roller shell: The diameter of the pellet roller/shell.

W = Width of Roller Shell

Bearings

Bearings are another crucial spare parts of pellet mills though it cannot be seen in the surface. Bearings can guarantee the stable operation of pellet mills, to reduce the friction in order to make sure the pellet mill run more smoothly and efficiently is the basic function of bearings. High quality bearings can ensure lower energy consumption, high efficiency and steady driving with low noise.

Other common spare parts

Apart from the leading spare parts, there are some other commonly used spare parts, such as

bolts, shearing bin, flanges and spacers, shafts and shells for rollers, etc. they are almost consumable parts and used a lot during the process of making pellets, so timely these spare parts should be maintained or changed.

Tips on maintenance of pellet mill spare parts

To prolong the lifespan of different spare parts of pellet mills, right operation and maintenance at regular time is quite necessary. Here are some simple tips for you to refer.

-

You should add lubricating oil to the transmission parts such as roller, front bearing of main shaft, etc. at regular time to ensure these parts of pellet mills can run flexibly and continuous and reduce the workload.

-

The lubricating oil of gear case should be changed at regular time. For new pellet mills, generally after half a month of operation to change oil, and change oil after every 1000 hours of continual operation, which can lengthen the lifespan of gear case.

-

Check all the connected parts, if they are loose or some there are some other mistakes every week to avoid affecting the continuous processing.

-

Make sure to choose high quality ring dies and pellet mill rollers because of their importance during the pellets making process, when wear is discovered, change them in time.

-

Every time, as long as the pellet mill is moved must adjust the clearance between ring dies and rollers. When pellet mill is blocked, must reduce pressure roller, clear material in inner wall of ring die, then adjust the clearance between ring die and pressure roller again, absolutely not allowed to start forcibly, which may make the transmission parts and bearing guard damaged by suffering violent vibration.

-

Please don’t produce overload, can’t exceed the producing capacity which pellet mill can withstand, which can protect the motor and slower the wear of parts.

Get in Touch Now!

Diesel pellet machine and screw conveyor are specially designed for our customer. The trial run is successful. Welcome to consult and order....

Diesel pellet machine and screw conveyor are specially designed for our customer. The trial run is successful. Welcome to consult and order....